GhostChemist

Expert

- Language

- 🇬🇧

- Joined

- Nov 20, 2022

- Messages

- 105

- Reaction score

- 235

- Points

- 43

Introduction

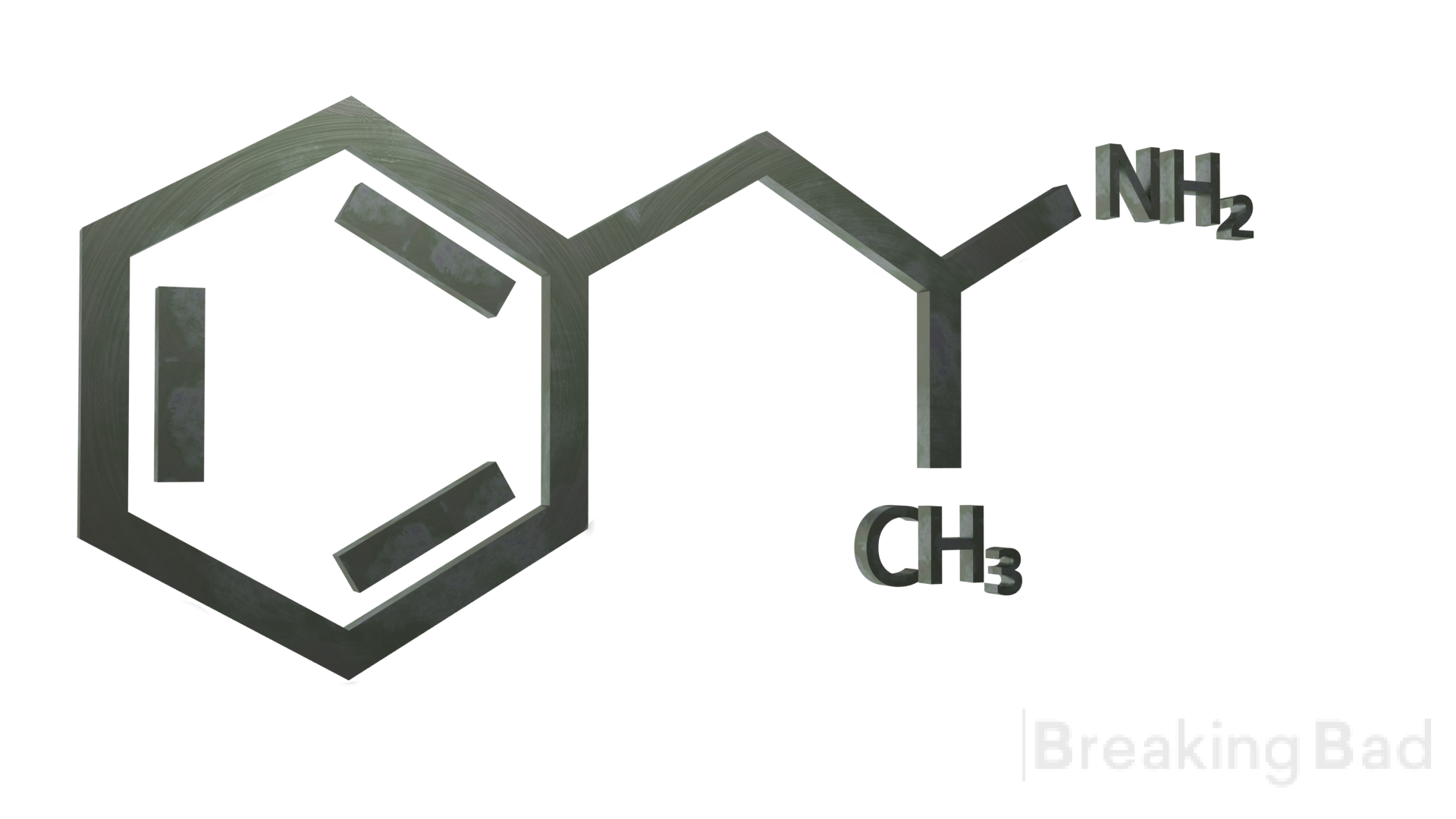

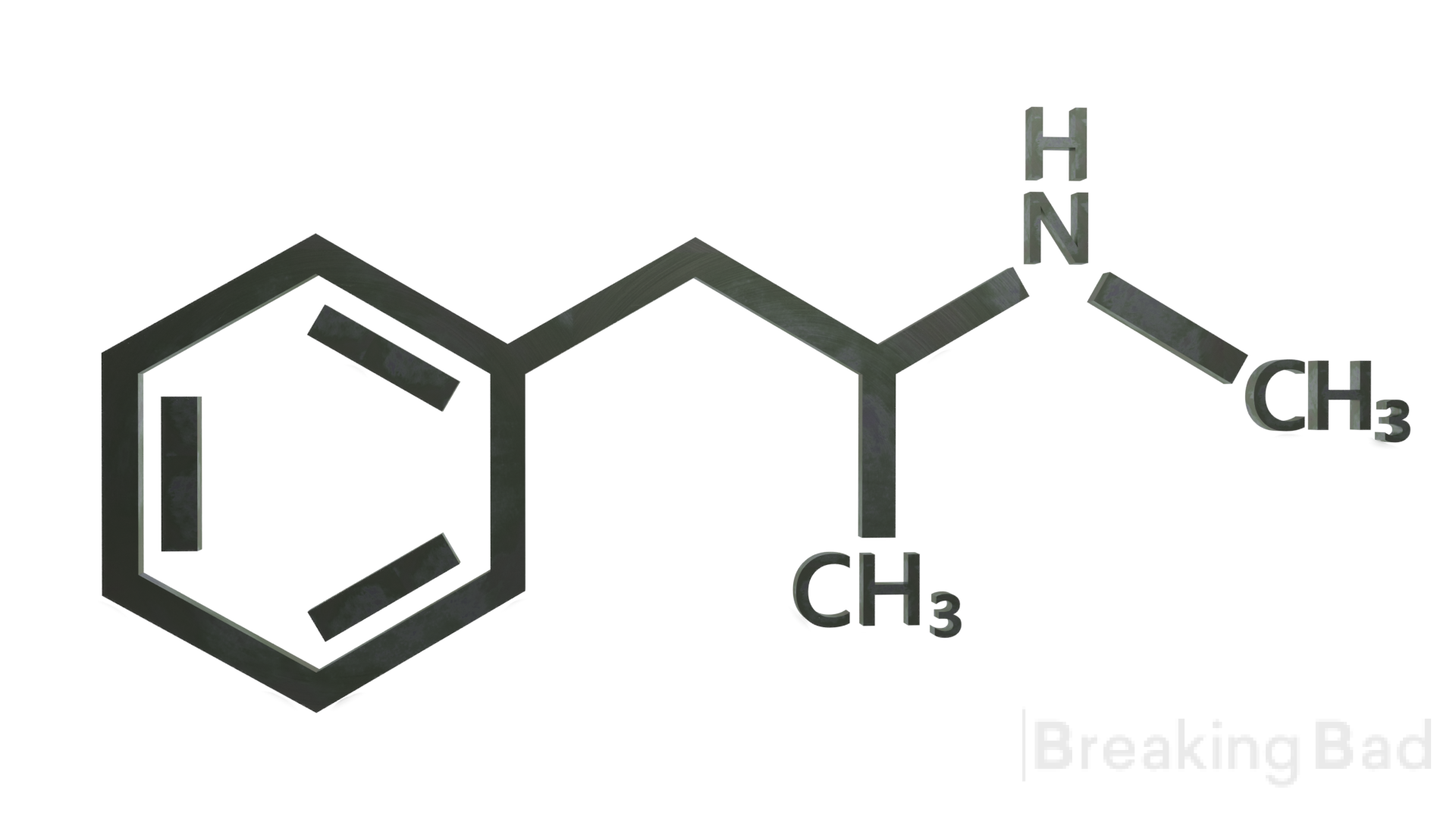

Amphetamine and methamphetamine are the most popular synthetic substances and both of them have significant value in modern drug sosiety. They are used at raves, parties, as doping, to get a high and so etc. BB Forum is unique platform in the World, which implements studies of these substances syntheses and post them publicly for free.

In this post, we want to share a comparation of several most popular syntheses methods of amphetamine and methamphetamine. All syntheses was conducted in one laboratory. You can compare their yield, reaction times, relative cost of product, syntheses pros and cons.

In this post, we want to share a comparation of several most popular syntheses methods of amphetamine and methamphetamine. All syntheses was conducted in one laboratory. You can compare their yield, reaction times, relative cost of product, syntheses pros and cons.

Comparative Characterization of Amphetamine Sulfate Synthesis Methods

Method | Product | Reagents and materials | A difficulty of the method | The time required to obtain 100 g | Yield from theory (%) | Relative cost per 100g | Advantages | Disadvantages |

Аmph | P2P; Al; HgCl2; NH3; H2O; EtOH or IPA; DCM; Acetone; Na2SO4; NaOH; H2SO4. Reactor of appropriate volume with a reflux condenser (2-10 liters); ice bath; heater; beakers; filters; Separatory funnel; pH indicator paper | Relatively simple | 1-1.5 d | 17-42% | 851$ | Relatively available reagents; simple equipment; quick execution | Small volume of P2P, maximum 100 g of P2P; high quality requirement for both the starting P2P and Al (minimum thickness of 14 µm); intense heating of the reaction mixture; possibility of overheating the reaction mixture and reducing yield; high likelihood of lab detection due to strong ammonia odor. | |

Аmph | P2P; Formamide or NH4HCO2; HCOOH; NaOH; HCl or H2SO4; DCM; Na2SO4; EtOH or IPA. Reactor of appropriate volume with a reflux condenser (2-10 liters); heater; beakers; filters; Separatory funnel; pH indicator paper | Medium | 1.5-2 d | 25% | 560$ | Possibility of process scalability; wide temperature range. | Very low yield; specific reagent formamide; contaminated product despite clean starting materials; lengthy process; high likelihood of lab detection due to strong ammonia odor | |

Аmph | Al; HgCl2; P2NP; Glacial acetic acid; NaOH; IPA or EtOH; H2O; DCM; Na2SO4; Acetone; H2SO4. Reactor of appropriate volume with a reflux condenser (2-10 liters); ice bath; heater; beakers; filters; Separatory funnel; pH indicator paper | Relatively simple | 1-1.5 d | 60-70% | 281$ | High yield; relatively available reagents; simple equipment; quick execution | Small mass of P2NP, maximum 100 g of P2NP; high quality requirement for the starting Al (minimum thickness of 14 µm); intense heating of the reaction mixture; possibility of overheating the reaction mixture and reducing yield; likelihood of lab detection due to the odor of acetic acid. | |

Аmph | Al; HgCl2; P2P; NH2OH*HCl; NaOH; IPA or EtOH; H2O; DCM; Na2SO4; Acetone; H2SO4. Reactor of appropriate volume with a reflux condenser (2-10 liters); ice bath; heater; beakers; filters; Separatory funnel; pH indicator paper | Relatively simple | 1-1.5 d | 36% | 734$ | Relatively available reagents; simple equipment; quick execution | Small volume of P2P, maximum 100-200 g of P2P; high quality requirement for both the starting P2P and Al (minimum thickness of 14 µm); intense heating of the reaction mixture; possibility of overheating the reaction mixture and reducing yield; high likelihood of lab detection due to strong ammonia odor. | |

Аmph | P2NP; NaBH4; IPA; CuCl2; NaOH; Acetone; H2SO4; H2O. A reactor of the appropriate volume with a stirrer; heater; beakers; filters; Separatory funnel; thermometer; Vacuum pump; pH indicator paper | Medium | 1-1.5 d | 60% | 487$ | Scalability potential of process; high yield; relatively pure product; alcohol odor can be masked by using air fresheners | Careful control of the initial exothermic process; specific reducing agent NaBH4. |

Comparative characterization of Methamphetamine hydrochloride synthesis methods

Method | Product | Reagents and materials | A difficulty of the method | The time required to obtain 100 g | Yield from theory (%) | Relative cost | Advantages | Disadvantages |

Meth | P2P; Al; HgCl2; СН3NH2; H2O; EtOH or IPA; DCM; Et2O; Acetone; Na2SO4; NaOH; HCl gas. Reactor of appropriate volume with a reflux condenser (2-10 liters); ice bath; heater; beakers; filters; Separatory funnel; pH indicator paper; HCl gas generator | Relatively simple | 1-1.5 d | 36-69% | 496$ | Relatively available reagents; simple equipment; quick execution. | Small volume of P2P, maximum 100 g of P2P; source of methylamine; high quality requirement for both the starting P2P and Al (minimum thickness of 14 µm); potential for intense heating of the reaction mixture with large loads; possibility of overheating the reaction mixture and reducing yield; high likelihood of lab detection due to strong odor of methylamine. | |

Meth | P2P; N-methylformamide; 14% aq HCl or 44% aq H2SO4; NaOH; H2O; DCM; EtOH; HCl gas; Et2O. A reactor of the appropriate volume with a stirrer; heater; beakers; filters; Separatory funnel; thermometer; Vacuum pump; pH indicator paper; HCl gas generator | Medium | 2-2.5 d | 30-38% | 851$ | Scalability potential of process; wide temperature range | Low yield; specific reagent n-methylformamide; impure product despite using clean starting components; lengthy process; high likelihood of lab detection due to strong ammonia odor. | |

Meth | P2P; СН3NH2 non aq; IPA abs; SiO2; NaBH4; Na2SO4; DCM; NH4Cl; HCl gas; Et2O; NaOH. A reactor of the appropriate volume with a stirrer; heater; beakers; filters; Separatory funnel; thermometer; Vacuum pump; pH indicator paper; ice bath; HCl gas generator | Medium | 1.5-2 d | 50-79% | 483$ | High yield, Scalability potential of process, relatively odorless | Specific reagents: methylamine in anhydrous alcohol and sodium borohydride; moisture-protected reactor system; efficient cooling of the reaction mixture. |

Prices was calculated according to https://www.sigmaaldrich.com/

Prices for reagents are taken for packing 1l or 1kg.Conclusion

As you can see, the numbers speak for themselves. A reagents availability and syntheses costs are essential characteristics. It is hard to overestimate this data. Every clandestine chemist, who has a plan to produce one of these substances, can evaluate their opportunities with help of these comparison tables and choose the suitable synthesis pathway. Then, they can open a synthesis tutorial and study all details. Part of these syntheses have video instructions.

Last edited: