GhostChemist

Expert

- Language

- 🇬🇧

- Joined

- Nov 20, 2022

- Messages

- 90

- Reaction score

- 224

- Points

- 33

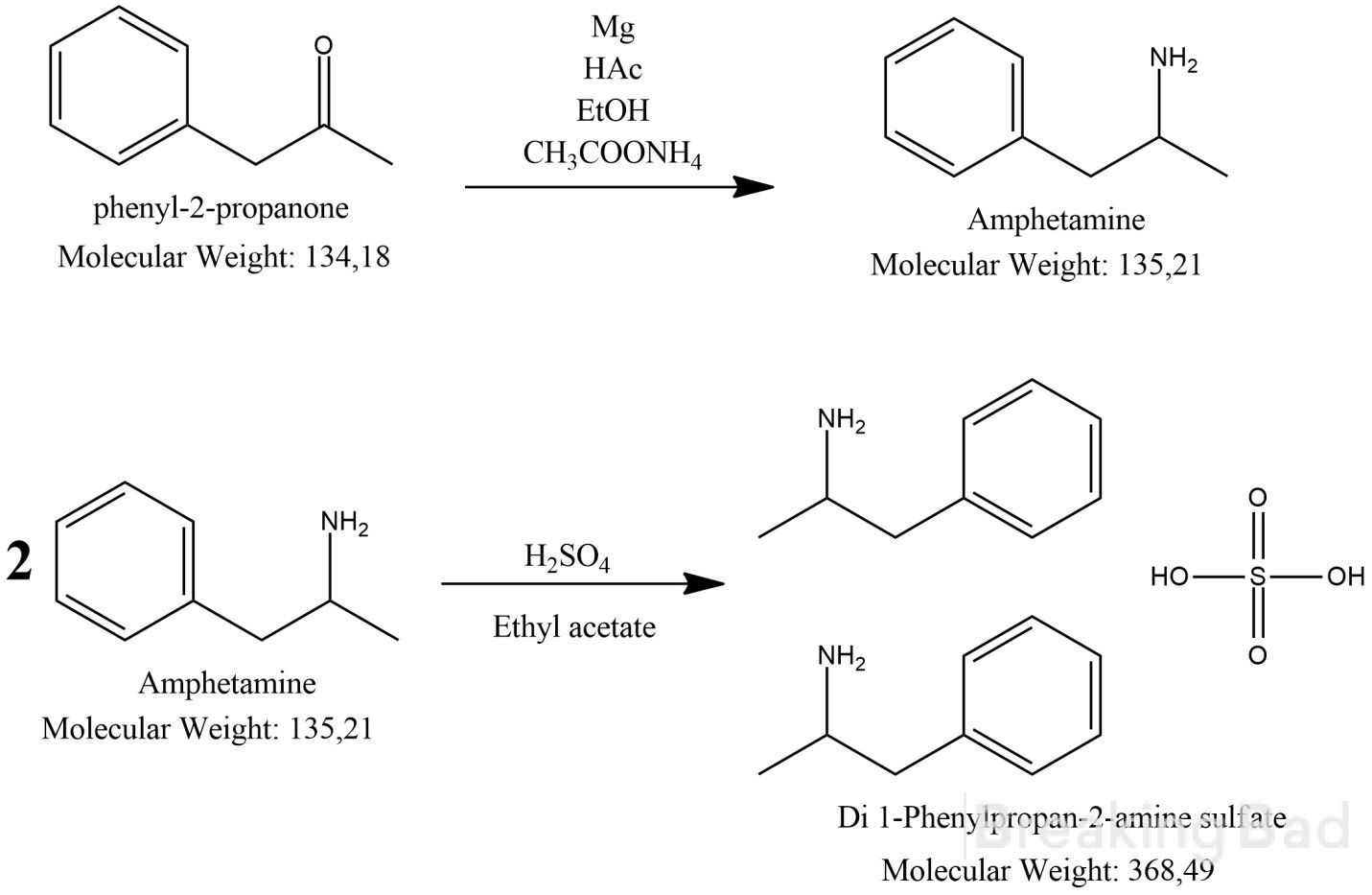

The reactions proceed according to Scheme 1.

Starting reagents and materials

The RM after reaction finished. Fig 6

After the reaction is complete, the mixture is filtered. Fig 7

Next, a 50 ml of 25% aqueous solution of NaOH is added until the pH reaches 8-10. During this process, a white precipitate of magnesium hydroxide will form, accompanied by the release of the amphetamine as a free base, characterized by a distinctive pleasant odor. Fig 8

100 mL of DCM is added to the filtrate for the extraction of the aphetamine free base. Fig 9

The amphetamine free base from RM is further extracted with several portions of DCM. If the reaction mass is too dense, water is added to dilute it. Fig 10

The extract in DCM is dried with anhydrous sodium sulfate. Fig 11

The drained extract of amphetamine in DCM. Fig 12

After DCM distilled off, the flask contains the oil of the amphetamine free base. Fig 13

Ethyl acetate added to the aphetamine free base and filtered to a glass beaker, and the residues in the flask are washed with 5 mL of ethyl acetate. Fig 14

Sulfuric acid is added to the aphetamine free base solution in ethyl acetate until the pH 7. A precipitate of aphetamine sulfate is forming. Fig 15

The precipitate of aphetamine sulfate is filtered through a paper filter and washed with 5 mL of ethyl acetate. The precipitate was air-dried. Fig 16

The yield of amine sulfate was 0.86 g or 12.5%

Scheme 1.

Starting reagents and materials

- 5 g purified P2P (P2P obtained through the reduction of P2NP with sodium borohydride and steam distill)

- 4.1 g Mg

- 37 г H3CCOONH4 (CAS 631-61-8)

- 250-300 ml H2O

- 80 ml EtOH 88%

- 30 ml HAc

- 500 ml DCM

- 5+5 ml Ethyl acetate

- 1-2 mL of concentrated sulfuric acid (83%)

- pH indicator paper

- 50 g of anhydrous sodium sulfate

- 50 mL of 25% NaOH (sodium hydroxide)

- Flasks

- Reflux condenser

- Separatory funnel

- Filter paper

- Funnels

- Beakers

- Heater

Fig 1

P2P is placed into a 1 L flask along with ammonium acetate and ethanol, and the mixture is well stirred. Fig 2Fig 2

Small portins of Mg is added to the obtained mixture. Fig 3Fig 3

During the reaction, portions 5-10 ml of acetic acid (HAc) is added. Fig 4Fig 4

The reaction proceeds smoothly and does not require cooling. The reaction is completed within 3-4 hours. Fig 5Fig 5

The RM after reaction finished. Fig 6

Fig 6

After the reaction is complete, the mixture is filtered. Fig 7

Fig 7

Next, a 50 ml of 25% aqueous solution of NaOH is added until the pH reaches 8-10. During this process, a white precipitate of magnesium hydroxide will form, accompanied by the release of the amphetamine as a free base, characterized by a distinctive pleasant odor. Fig 8

Fig 8

100 mL of DCM is added to the filtrate for the extraction of the aphetamine free base. Fig 9

Fig 9

The amphetamine free base from RM is further extracted with several portions of DCM. If the reaction mass is too dense, water is added to dilute it. Fig 10

Fig 10

The extract in DCM is dried with anhydrous sodium sulfate. Fig 11

Fig 11

The drained extract of amphetamine in DCM. Fig 12

Fig 12

After DCM distilled off, the flask contains the oil of the amphetamine free base. Fig 13

Fig 13

Ethyl acetate added to the aphetamine free base and filtered to a glass beaker, and the residues in the flask are washed with 5 mL of ethyl acetate. Fig 14

Fig 14

Sulfuric acid is added to the aphetamine free base solution in ethyl acetate until the pH 7. A precipitate of aphetamine sulfate is forming. Fig 15

Fig 15

The precipitate of aphetamine sulfate is filtered through a paper filter and washed with 5 mL of ethyl acetate. The precipitate was air-dried. Fig 16

Fig 16

The yield of amine sulfate was 0.86 g or 12.5%