William D.

Expert

- Joined

- Jul 19, 2021

- Messages

- 1,056

- Reaction score

- 1,320

- Points

- 113

Introduction

Reagents:

1. Valerophenone (CAS 1009-14-9) 1 kg is weighed and poured into the reactor.

2. Hydrobromic acid (HBr) 1000 g 48% is added.

3. The reaction mixture is stirred vigorously for 5 minutes.

4. Hydrogen peroxide (H2O2) 300 g 35% is added into the drip funnel and installed onto the reactor neck.

5. A drop funnel tap is opened and hydrogen peroxide is added dropwise with vigorous stirring.

6. Look at the color of the mixture. Color may vary from yellow to red. Hydrogen peroxide is added so that mixture is discolored.

7. The temperature is maintained below 65 ℃. The H2O2 dripping is stopped in case the temperature is risen.

8. The reaction mixture is vigorously stirred for 1.5 h.

9. Distilled water is added and the reaction mixture is stirred for 5 minutes.

10. The stirring is stopped and the reaction mixture is separated into two layers. The target layer is on the bottom, water is on the top layer.

11. The water layer is removed with help of a vacuum pump through the reactor neck.

12. An aqueous alkaline solution is added and stirred for 5 minutes.

13. Steps 9, 10, 11 are repeated.

14. The resulting product is left in the reactor.

Stage 2. Amination.

1. Ethyl acetate 4 L is placed into a reactor with 2'-Bromovalerophenone 1.5 kg and stirred 5 minutes.

2. A drip funnel is installed at the reactor neck and pyrrolidine 1150 ml (CAS 123-75-1) is added into this funnel.

3. A drop funnel tap is opened and pyrrolidine is added dropwise with vigorous stirring.

4. The temperature is maintained below 65 ℃.

5. The reaction mixture is vigorously stirred for 1 hour after completion of the pyrrolidine addition.

8. A reactor vacuum pump and a chiller pump of reflux condenser are turned on.

9. The most part of ethyl acetate is distilled off.

10. A vacuum pump is stopped and acetone is added into the reactor. The stirring is continued.

11. Hydrochloric acid is added into the drip funnel on the reactor neck.

12. Hydrochloric acid is added to pH 5. A small amount of reaction mixture is drained from the bottom reactor tap to control pH with a litmus paper (also, you can use glass rod for this goal). The sample is returned to the reactor.

13. After that, the reaction mixture is poured into a beaker and put into a freezer for 12 hours.

Stage 3. alpha-PVP Hydrochloride Filtration.

1. A vacuum filtration system is installed (nutsche filter, filter cloth, vacuum pump).

2. A vacuum pump is turned on.

3. The reaction mixture is poured from the beaker (from step 13 stage 2) to Buchner funnel.

4. The reaction mixture is filtered and pressed until a solid is obtained.

5. A cold acetone is poured into Buchner funnel to cover the whole solid.

6. Acetone is filtered and product is washed. Step 5 is repeated in case the solid substance is not white.

7. The content of Buchner funnel is poured into the Pyrex dish for drying procedure after the acetone filtration and the white solid obtaining.

8. The Pyrex dish is placed in a dry place at room temperature.

9. The product is dried to constant mass. Product is mixed and crushed periodically in order to rise drying speed.

Stage 4. alpha-PVP Isomer Separation.

1. a-PVP HCl 10.0 g, 35.5 mmol is dissolved in minimum volume of distilled water .

1. a-PVP HCl 10.0 g, 35.5 mmol is dissolved in minimum volume of distilled water .

2. Na2CO3 20% aq solution is added to reach pH 8-9.

3. The mixture is extracted with Et2O 50 ml.

4. Ether extract is separated in a separatory funnel, then Et2O is distilled off.

5. a-PVP free base is dissolved in EtOH (50 ml).

6. Ethanol solution of a-PVP free base is heated to 70 ℃.

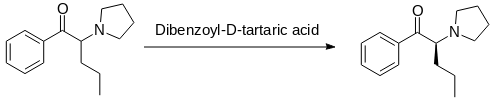

7. Dibenzoyl-D-tartaric acid 12.7 g, 35.5 mmol is added.

8. The solution is refluxed with a reflux condenser for 1 minute and cooled to a room temperature.

9. A solvent is distilled off.

10. The residue is dissolved in CH2Cl2 (530 mL). Hexane (700 mL) is added with stirring.

11. The resulting crystals (9.1 g) are collected by filtration through a Buchner flask and funnel after 3 days.

12. Three consecutive recrystallizations from CH2Cl2/hexane (300/400 mL) are given a single diastereoisomer (6.1 g, 61%);

13. Steps 1, 2, 3 are repeated with salt from step 11.

14. A cold acetone is added.

15. Hydrochloric acid (HCl) is added to reach pH 5.

16. Pruduced crystals from step 15 are filtered and air dried.

This topic is represented alpha-PVP synthesis way in a medium scale 1-10 kg. There are elaborated video tutorials, which are allowed to produce this substance to anybody. Also, you can find here a list of necessary equipment and reagents.

Equipment and glassware:

- Round bottom flask;

- Retort stand and clamp for securing apparatus;

- Reflux condenser;

- Drip funnel;

- pH indicator papers;

- Beakers;

- Vacuum source;

- Laboratory scale (1-2000 g is suitable);

- Measuring cylinders 100, 500 and 1000 mL;

- Top stirrer with heating plate;

- Glass rod and spatula;

- Separatory funnel 1 L ;

- Laboratory grade thermometer;

- Buchner flask and funnel;

- Vacuum source;

- Filter paper;

- Rotary evaporator;

- Conventional funnel;

Reagents:

- Valerophenone (CAS 1009-14-9) 1 kg;

- Hydrobromic acid (HBr) 1 kg 48%;

- Hydrogen peroxide (H2O2) 300 g 35%;

- Pyrrolidine 1100 ml (CAS 123-75-1);

- Ethyl acetate 4 L;

- Sodium carbonate (Na2CO3) 20% aq solution;

- Diethyl ether (Et2O) 50 ml;

- EtOH 50 mL;

- Dibenzoyl-D-tartaric acid 12.7 g, 35.5 mmol;

- Dichloromethane (CH2Cl2) 830 mL;

- Hexane 1100 mL;

- Hydrochloric acid conc. 35% (HCl);

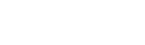

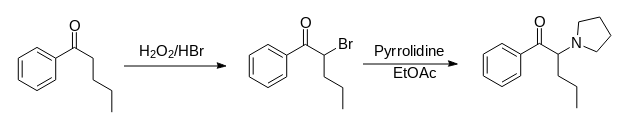

Stage 1. Halogenation.2-Bromovalerophenone synthesis from valerophenone

Valerophenone halogenation (CAS 1009-14-9) to 2-Bromovalerophenone (CAS 49851-31-2)...

2. Hydrobromic acid (HBr) 1000 g 48% is added.

3. The reaction mixture is stirred vigorously for 5 minutes.

4. Hydrogen peroxide (H2O2) 300 g 35% is added into the drip funnel and installed onto the reactor neck.

5. A drop funnel tap is opened and hydrogen peroxide is added dropwise with vigorous stirring.

6. Look at the color of the mixture. Color may vary from yellow to red. Hydrogen peroxide is added so that mixture is discolored.

7. The temperature is maintained below 65 ℃. The H2O2 dripping is stopped in case the temperature is risen.

8. The reaction mixture is vigorously stirred for 1.5 h.

9. Distilled water is added and the reaction mixture is stirred for 5 minutes.

10. The stirring is stopped and the reaction mixture is separated into two layers. The target layer is on the bottom, water is on the top layer.

11. The water layer is removed with help of a vacuum pump through the reactor neck.

12. An aqueous alkaline solution is added and stirred for 5 minutes.

13. Steps 9, 10, 11 are repeated.

14. The resulting product is left in the reactor.

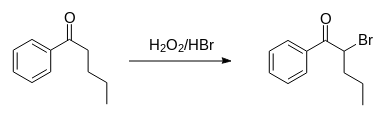

Stage 2. Amination.

α-PVP/MDPV synthesis from 2-Bromovalerophenone

α-PVP hydrochloride synthesis from 2-Bromovalerophenone (cas 49851-31-2)...

2. A drip funnel is installed at the reactor neck and pyrrolidine 1150 ml (CAS 123-75-1) is added into this funnel.

3. A drop funnel tap is opened and pyrrolidine is added dropwise with vigorous stirring.

4. The temperature is maintained below 65 ℃.

5. The reaction mixture is vigorously stirred for 1 hour after completion of the pyrrolidine addition.

8. A reactor vacuum pump and a chiller pump of reflux condenser are turned on.

9. The most part of ethyl acetate is distilled off.

10. A vacuum pump is stopped and acetone is added into the reactor. The stirring is continued.

11. Hydrochloric acid is added into the drip funnel on the reactor neck.

12. Hydrochloric acid is added to pH 5. A small amount of reaction mixture is drained from the bottom reactor tap to control pH with a litmus paper (also, you can use glass rod for this goal). The sample is returned to the reactor.

13. After that, the reaction mixture is poured into a beaker and put into a freezer for 12 hours.

Stage 3. alpha-PVP Hydrochloride Filtration.

1. A vacuum filtration system is installed (nutsche filter, filter cloth, vacuum pump).

2. A vacuum pump is turned on.

3. The reaction mixture is poured from the beaker (from step 13 stage 2) to Buchner funnel.

4. The reaction mixture is filtered and pressed until a solid is obtained.

5. A cold acetone is poured into Buchner funnel to cover the whole solid.

6. Acetone is filtered and product is washed. Step 5 is repeated in case the solid substance is not white.

7. The content of Buchner funnel is poured into the Pyrex dish for drying procedure after the acetone filtration and the white solid obtaining.

8. The Pyrex dish is placed in a dry place at room temperature.

9. The product is dried to constant mass. Product is mixed and crushed periodically in order to rise drying speed.

Stage 4. alpha-PVP Isomer Separation.

2. Na2CO3 20% aq solution is added to reach pH 8-9.

3. The mixture is extracted with Et2O 50 ml.

4. Ether extract is separated in a separatory funnel, then Et2O is distilled off.

5. a-PVP free base is dissolved in EtOH (50 ml).

6. Ethanol solution of a-PVP free base is heated to 70 ℃.

7. Dibenzoyl-D-tartaric acid 12.7 g, 35.5 mmol is added.

8. The solution is refluxed with a reflux condenser for 1 minute and cooled to a room temperature.

9. A solvent is distilled off.

10. The residue is dissolved in CH2Cl2 (530 mL). Hexane (700 mL) is added with stirring.

11. The resulting crystals (9.1 g) are collected by filtration through a Buchner flask and funnel after 3 days.

12. Three consecutive recrystallizations from CH2Cl2/hexane (300/400 mL) are given a single diastereoisomer (6.1 g, 61%);

13. Steps 1, 2, 3 are repeated with salt from step 11.

14. A cold acetone is added.

15. Hydrochloric acid (HCl) is added to reach pH 5.

16. Pruduced crystals from step 15 are filtered and air dried.

Last edited by a moderator: