- Joined

- May 31, 2022

- Messages

- 209

- Reaction score

- 146

- Points

- 43

Hello, here I attach a simple and simple synthesis of bkmdma with photos of the process and the finished product.

1-To begin with, two plastic drums of approximately 25 liters were brought and inside a drum, an exact 500g of C.A.S: 52190-28-0 of excellent quality was dissolved in 2.5 liters of DCM (dichloromethane) and with an electric drill with a bit mixing concrete was stirred until the complete dissolution of the precursor, this did not take more than a few minutes.

2- now added 1litre of methylamine in in different portions at the rate of 250ml every 10 minutes approximately. At no time was the temperature increase noted since all the reagents were cold before starting, at no time was heat used for this reaction. once all the methylamine was added it was allowed to stir for 40 minutes until no more methylamine gas fumes were observed.

3- 50 minutes after the beginning of the reaction, the agitation was stopped and we waited a few minutes until the 2 layers were separated: the base and and the aqueous layer formed from methylamine and still traces of product, for this another plastic drum was used and the layer The aqueous layer was separated to the new drum for its subsequent extractions of some of the product that remained in the aqueous layer. For this, ethyl acetate was used. 100 milliliters of ethyl acetate were added three times each time to the aqueous layer and it was collected to add it. to the other tambo where the base was reserved.

4- Once the 3 extractions were united with the base in the same drum, the base was cleaned, for this abundant water was added and stirred together with the base and once the water was separated, all the water was emptied from the other drum thus leaving the clean methylone base in the first tube. This cleaning process was repeated at least 3 times until the base did not give off any smell of methylamine. Now a good handful of magnesium sulfate was added to the drum that contained the base and it was left to dry for 20 minutes, during which time it was used to get rid of the cleaning of water deposited in the other bucket. As can be seen, the entire synthesis is being carried out only with the help of 2 plastic buckets and a normal masonry drill with a bit to mix the mortar and cement and with a good source of water near the production area.

5- formation of methylone hydrochloride, for this, sufficient 36% HCL was prepared in a beaker with a little cold acetone, once again the electric drill was turned on and the base was constantly stirred and the hcl was added in small portions and measure the ph until reaching ph 5, at that moment they stopped adding more HCL but the base was kept stirring for a little longer, when we stopped the drill we observed a lot of hydrochloride both floating and on the walls, the bottom of the cube and attached to the drill .

6- filtration process. For this, the other cube was taken again and a filter was placed on top of it, firmly attached with tweezers and all the solution was filtered, leaving the methylone trapped in the filter. The cube and the hole that contained methylone were scraped and drained well. it was ignited and air dried to yield 90% dry of the actual weight of precursor.

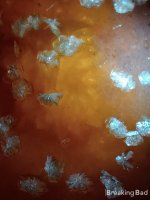

7- recristalization . 490g of Methylone HCL were put to recrystallization with water and acetone in the proportion of: for each gram of HCL 1.5ml of distilled water and 1ml of acetone which formed some beautiful crystals and at the same time purified its purity to reach a good percentage of pure bkmdma crystal.

1-To begin with, two plastic drums of approximately 25 liters were brought and inside a drum, an exact 500g of C.A.S: 52190-28-0 of excellent quality was dissolved in 2.5 liters of DCM (dichloromethane) and with an electric drill with a bit mixing concrete was stirred until the complete dissolution of the precursor, this did not take more than a few minutes.

2- now added 1litre of methylamine in in different portions at the rate of 250ml every 10 minutes approximately. At no time was the temperature increase noted since all the reagents were cold before starting, at no time was heat used for this reaction. once all the methylamine was added it was allowed to stir for 40 minutes until no more methylamine gas fumes were observed.

3- 50 minutes after the beginning of the reaction, the agitation was stopped and we waited a few minutes until the 2 layers were separated: the base and and the aqueous layer formed from methylamine and still traces of product, for this another plastic drum was used and the layer The aqueous layer was separated to the new drum for its subsequent extractions of some of the product that remained in the aqueous layer. For this, ethyl acetate was used. 100 milliliters of ethyl acetate were added three times each time to the aqueous layer and it was collected to add it. to the other tambo where the base was reserved.

4- Once the 3 extractions were united with the base in the same drum, the base was cleaned, for this abundant water was added and stirred together with the base and once the water was separated, all the water was emptied from the other drum thus leaving the clean methylone base in the first tube. This cleaning process was repeated at least 3 times until the base did not give off any smell of methylamine. Now a good handful of magnesium sulfate was added to the drum that contained the base and it was left to dry for 20 minutes, during which time it was used to get rid of the cleaning of water deposited in the other bucket. As can be seen, the entire synthesis is being carried out only with the help of 2 plastic buckets and a normal masonry drill with a bit to mix the mortar and cement and with a good source of water near the production area.

5- formation of methylone hydrochloride, for this, sufficient 36% HCL was prepared in a beaker with a little cold acetone, once again the electric drill was turned on and the base was constantly stirred and the hcl was added in small portions and measure the ph until reaching ph 5, at that moment they stopped adding more HCL but the base was kept stirring for a little longer, when we stopped the drill we observed a lot of hydrochloride both floating and on the walls, the bottom of the cube and attached to the drill .

6- filtration process. For this, the other cube was taken again and a filter was placed on top of it, firmly attached with tweezers and all the solution was filtered, leaving the methylone trapped in the filter. The cube and the hole that contained methylone were scraped and drained well. it was ignited and air dried to yield 90% dry of the actual weight of precursor.

7- recristalization . 490g of Methylone HCL were put to recrystallization with water and acetone in the proportion of: for each gram of HCL 1.5ml of distilled water and 1ml of acetone which formed some beautiful crystals and at the same time purified its purity to reach a good percentage of pure bkmdma crystal.

Attachments

-

vrh3Uu65TH.jpeg3.1 MB · Views: 937

vrh3Uu65TH.jpeg3.1 MB · Views: 937 -

0X7PfqWpSc.jpeg3.2 MB · Views: 568

0X7PfqWpSc.jpeg3.2 MB · Views: 568 -

nmruQUViZM.jpeg4 MB · Views: 529

nmruQUViZM.jpeg4 MB · Views: 529 -

LkDQEInp57.jpeg2.8 MB · Views: 520

LkDQEInp57.jpeg2.8 MB · Views: 520 -

7AhWKzkyVX.jpg3.8 MB · Views: 528

7AhWKzkyVX.jpg3.8 MB · Views: 528 -

HQbnjcyo8J.jpg3.1 MB · Views: 514

HQbnjcyo8J.jpg3.1 MB · Views: 514 -

bHlhQqDVtZ.jpg2.7 MB · Views: 519

bHlhQqDVtZ.jpg2.7 MB · Views: 519 -

CnZlKL9z6S.jpg335.7 KB · Views: 503

CnZlKL9z6S.jpg335.7 KB · Views: 503 -

VakztjSOrE.jpg2.7 MB · Views: 561

VakztjSOrE.jpg2.7 MB · Views: 561