WillD

Expert

- Joined

- Jul 19, 2021

- Messages

- 774

- Reaction score

- 1,058

- Points

- 93

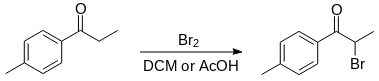

Reaction scheme:

Reagents:

Reagents:

Synthesis in DCM:

Synthesis in Acetic acid:

- 4-methylpropiophenone (cas 5337-93-9) - 1000 g;

- Dichloromethane (DCM) or glacial acetic acid (GAA) - 3000 ml;

- Bromine (Br2) - 1080g, 348 ml;

- Sodium bicarbonae (NaHCO3) solution;

- Distilled water;

- Magnesium sulphate (MgSO4);

- Three necked round bottom flask 10 L;

- Retort stand and clamp for securing apparatus;

- Top stirrer;

- Drip funnel 500 mL;

- Separatory funnel (optional);

- Glass rod and spatula;

- Heating plate;

- Laboratory grade thermometer;

- Laboratory scale (1-1000 g is suitable);

- Measuring cylinders 100 mL and 1 L;

- Funnel;

- Filter paper;

- pH Indicator paper;

- Rotovap machine;

- Vacuum source;

- Buchner flask (large) and funnel;

- Beakers 1000 ml x2 and 2000 ml x2;

Bromine has an orange-red fumes with a sharp smell. Bromine is rapidly absorbed by skin and caused hard long non-healing burns and ulcers. A bromine vapors are caused a burning sensation in nose and throat during contact with mucous membranes. All manipulations with bromine and syntheses have to be carried out in an exhaust fume hood with rubber gloves, protective googles and mask. Bromine should be poured into a flat-bottomed flask through a conical funnel, which is fixed above the flask on retort stand. A tip of the funnel must be inside of the flask. It is necessary to thoroughly remove a lubricant from grinding surfaces of crane and clutches of a drip funnel and clean them with phosphoric acid .

Synthesis in DCM:

1. 4-Methylpropyophenone 1000 g is placed into a 10 L flask.

2. Dichloromethane (DCM) 3000 ml is poured there and stirred for 5 min.

3. The stirring is stopped. Liquid bromine (Br2) 1080 g, 348 ml is added to a drip funnel.

4. Bromine (Br2) 30-50 ml is added dropwise into the flask from the drip funnel.

5. Bromine have to fall at the flask bottom.

6. Bromine must be dissolved on the bottom and the mixture have to be discolored.

7. The mixture is heated to 30 °C, if the solution isn't discolored.

8. The mixture slightly stirred and the stirring is stopped when bromine is dissolved.

9. A second smaller bromine portion is added to the mixture. It is stirred again after discoloration.

10. A third even less bromine portion is added to the mixture. It is stirred again after discoloration.

11. If bromine is dissolved immediately, bromine addition is continued dropwise, not by portions, with a constant stirring.

12. The reaction mixture is stirred 30 min after complete bromine addition.

13. A saturated sodium bicarbonae (NaHCO3) solution is added to the flask and stirred for 5 min. Then, layers are separated.

14. Distilled water is added to the organic layer, the mixture is stirred for 5 min. Layers are separated.

15. Organic layer is dried over sodium sulphate (MgSO4) and filtered from solids. Organic solvent is distilled off with vacuum form the solution in case you need dry 2-bromo-4'-methylpropiophenone (cas 1451-82-7).

16. The mixture is left for further reaction with approximate 2-bromo-4'-methylpropiophenone (cas 1451-82-7) yield 1500 g in case you need to carry out methylamination in DCM.

2. Dichloromethane (DCM) 3000 ml is poured there and stirred for 5 min.

3. The stirring is stopped. Liquid bromine (Br2) 1080 g, 348 ml is added to a drip funnel.

4. Bromine (Br2) 30-50 ml is added dropwise into the flask from the drip funnel.

5. Bromine have to fall at the flask bottom.

6. Bromine must be dissolved on the bottom and the mixture have to be discolored.

7. The mixture is heated to 30 °C, if the solution isn't discolored.

8. The mixture slightly stirred and the stirring is stopped when bromine is dissolved.

9. A second smaller bromine portion is added to the mixture. It is stirred again after discoloration.

10. A third even less bromine portion is added to the mixture. It is stirred again after discoloration.

11. If bromine is dissolved immediately, bromine addition is continued dropwise, not by portions, with a constant stirring.

12. The reaction mixture is stirred 30 min after complete bromine addition.

13. A saturated sodium bicarbonae (NaHCO3) solution is added to the flask and stirred for 5 min. Then, layers are separated.

14. Distilled water is added to the organic layer, the mixture is stirred for 5 min. Layers are separated.

15. Organic layer is dried over sodium sulphate (MgSO4) and filtered from solids. Organic solvent is distilled off with vacuum form the solution in case you need dry 2-bromo-4'-methylpropiophenone (cas 1451-82-7).

16. The mixture is left for further reaction with approximate 2-bromo-4'-methylpropiophenone (cas 1451-82-7) yield 1500 g in case you need to carry out methylamination in DCM.

Synthesis in Acetic acid:

1. Previous synthesis steps 1-12 are same, the DCM is replaced to acetic acid.

2. Cold distilled water 3 L is gradually poured to the mixture and stirred.

3. 2-Bromo-4'-methylpropiophenone (cas 1451-82-7) is crystallized during water addition and stirred.

4. The 2-bromo-4'-methylpropiophenone product is filtred on Buchner flask and funnel.

5. The product crystals are washed with sodium bicarbonae (NaHCO3) solution, filtered and washed again with distilled water to neutral pH 6.5-7.

6. 2-Bromo-4'-methylpropiophenone (cas 1451-82-7) is filtered on Buchner flask and funnel, and air dried (or in vacuum desiccator) to a constant mass.

2. Cold distilled water 3 L is gradually poured to the mixture and stirred.

3. 2-Bromo-4'-methylpropiophenone (cas 1451-82-7) is crystallized during water addition and stirred.

4. The 2-bromo-4'-methylpropiophenone product is filtred on Buchner flask and funnel.

5. The product crystals are washed with sodium bicarbonae (NaHCO3) solution, filtered and washed again with distilled water to neutral pH 6.5-7.

6. 2-Bromo-4'-methylpropiophenone (cas 1451-82-7) is filtered on Buchner flask and funnel, and air dried (or in vacuum desiccator) to a constant mass.

Last edited by a moderator: